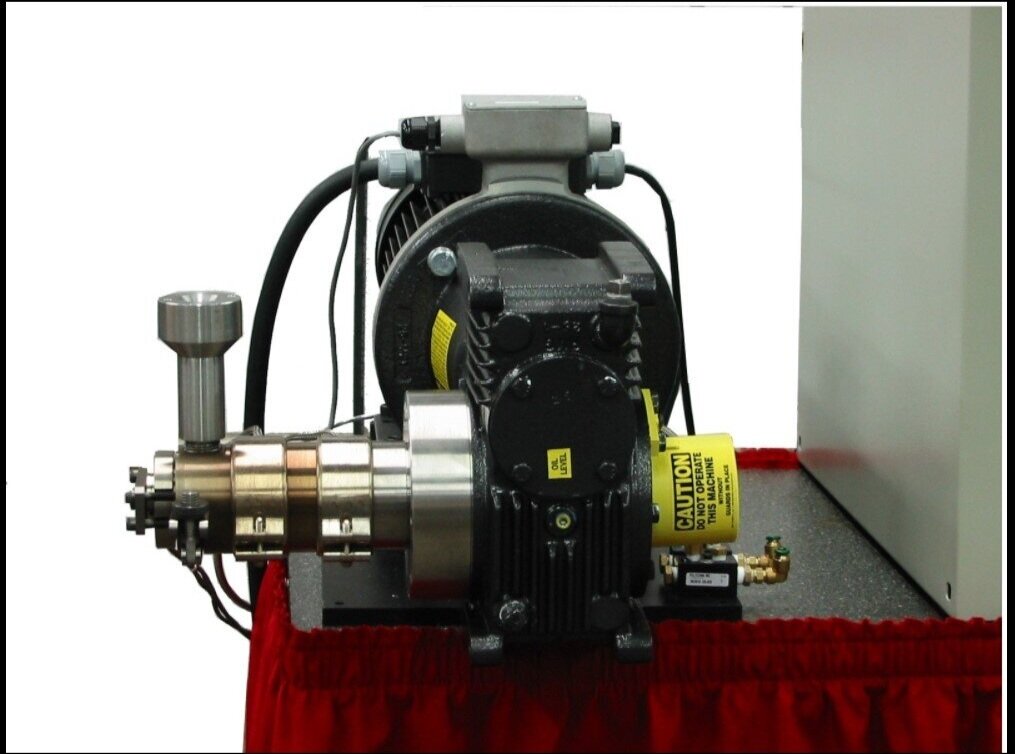

Randcastle's Micro Batch Mixer

Compound small batches into a strand without scraping hot polymer from rotors! Save time, make better mixes, then scale results to our compounding screws.

This mixer is a Randcastle Innovation. The RM-1000-4 is designed to work with samples in the 10 gram range. We can expand the range to as little as 1 gram and up to 100 grams.

The advantage of the compounder (besides the batch size) include:

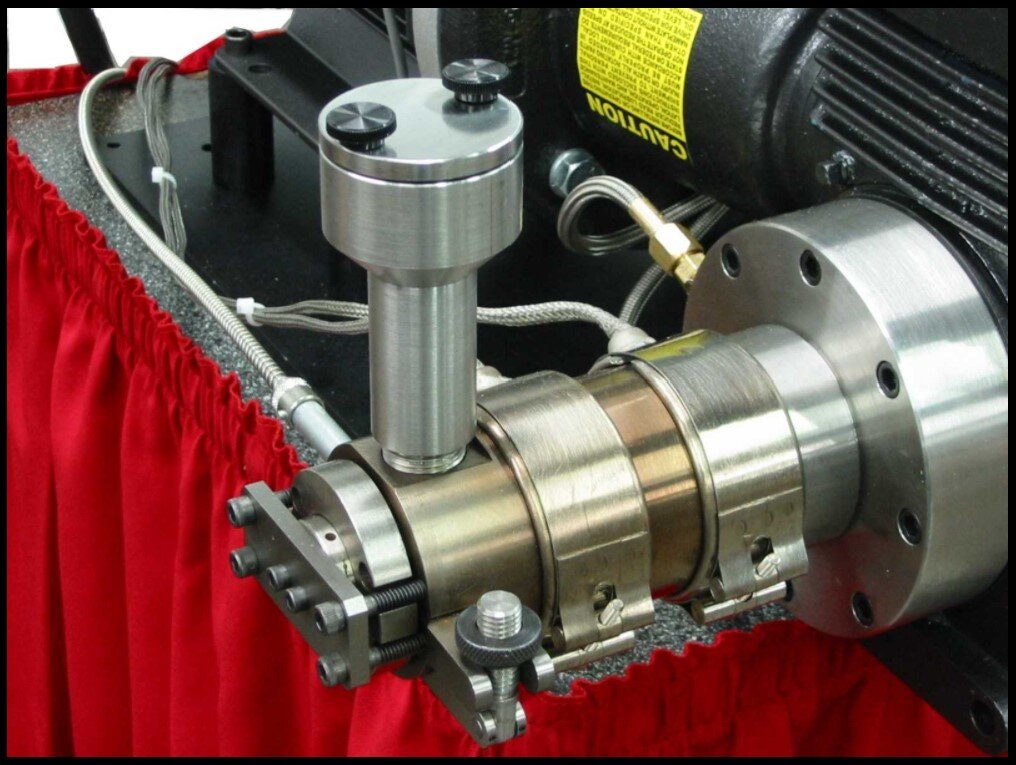

Scaling: This mixer uses the same patent pending technology as our Recirculator mixer so it scales well to single screw extruders. This is a Randcastle first as the other batch compounders do not scale well to the single screw extruder.

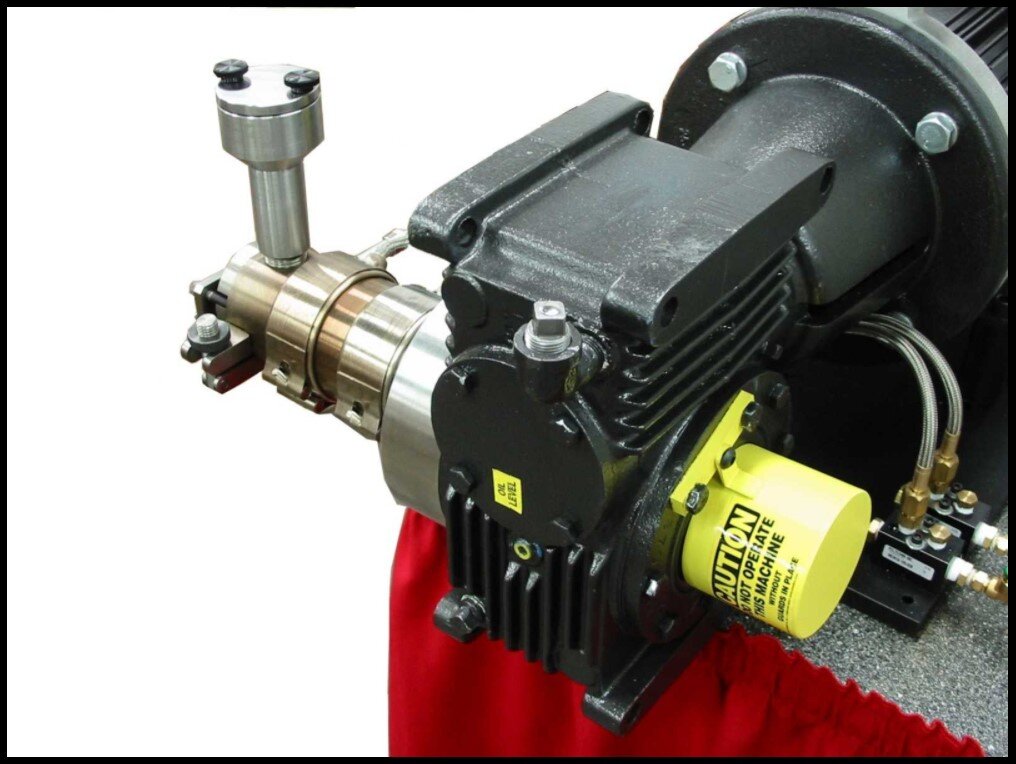

Output: We extrude about 5 grams of mixed material through the die without disassembly. This makes for ease of operation and cleanliness.

Extrusion: The batch mixer can be removed and the same transmission and control system used for single screw extrusion with the Recirculator.

FACILE TPO DISPERSION USING EXTENSIONAL MIXING: SFEM BATCH MIXERS’ peer reviewed technical paper presented by Dow Chemical’s Stéphane Costeux at Antec 2011 concluded: 1) “…the Randcastle SFEM batch mixer indicate that its dispersive capabilities are superior to the Mixing Bowl, while reducing the amount of material and time per blend. 2) It is confirmed that the SFEM’s primary deformation mode is elongational, which also contributes to limiting shear heating effects. 3) The same SFEM elements can be added to a single screw extruder, which achieve even better performance, which is encouraging from a scale-up standpoint. 4) This technology is suitable for single-screw extrusion of TPOs and other immiscible blends.

A NOVEL MICRO-BATCH MIXER THAT SCALES TO A SINGLE SCREW COMPOUNDER Written with Rutgers University’s Jennifer Lynch and Tom Nosker for Antec 2008, the paper concludes: The micro-batch mixer is shown to produce similar mixedness as the SSE for a variety of materials systems because of its similar geometry to the SSE compounder with SFEM elements. The mixing times are fairly short and comparable to extrusion residence times. This micro-batch mixer adds a powerful tool for the polymer researcher because only small quantities of material are necessary, and these experiments successfully scale-up to large-scale extrusion processing equipment. The micro-batch mixer is a vital, simple piece of equipment that provides results quickly and conveniently.

SFEM BATCH MIXERS: Elongational batch mixers from 1 to 200cc capacity: Dispersity 10 times better than “mixing bowls.” Mixtures in one third the time of “mixing bowls.” Compounding equal to a twin screw extruder. Scales to our single screw mixers (same geometry). Conveniently extrudes your material into a strand: No need to scrape melted material from hot rotors. Quick strand cooling eliminate degradation. No need to grind scrapings for later processing. Find details in peer reviewed technical papers.

FACILE TPO DISPERSION USING EXTENSIONAL MIXING

Stéphane Costeux, Mark Barger, Keith Luker*, Anand Badami, Kim Walton

The Dow Chemical Company, Midland, MI (U.S.A.)

*Randcastle Extrusion Systems, Inc., Cedar Grove, NJ (U.S.A.)

A NOVEL MICRO-BATCH MIXER THAT SCALES TO A SINGLE SCREW COMPOUNDER

Jennifer K. Lynch, Rutgers University

Thomas J. Nosker, Rutgers University

Keith Luker, Randcastle Extrusion Systems, Inc., Cedar Grove, NJ